Our experienced team is capable of completing high-volume metal finishing tasks in the shortest time. Metal finishing is a critical step that affects the appearance and quality of the final product. We utilize state-of-the-art finishing equipment and techniques to ensure that the surface of your product is smooth and shiny. Moreover, our finishing services can be customized to meet your specific needs.

Weshining plasma polishing technology is an advanced method that uses plasma to remove nanoscale materials from metal surfaces, making the surface smooth and shiny. Its material removal speed is 10-30 times faster than traditional electrolytic polishing. No corrosive chemicals, no harmful emissions. It is currently an ideal choice for 3D printing or additive manufacture metal to do finishing in a reliable and environmentally friendly way.

Weshining polymer is a polishing system suitable for high efficiency and excellent surface treatment. With our own-developed media,it accurately removes substances at rough peaks and maintain the part’s shape.Whatsmore,it handles blind corners that cannot be touched by mechanical polishing to achieve the best effect of uniform and high glossiness in surface treatment.

The Complementary Pairs is Weshining’s solution for industry value. It helps customers build digital production faster and better to realize business innovation and transformation.

We look forward to working together with you to improve the quality and performance of the products.

Material: Titanium alloy

Manufacturing : Cast

Polishing machine: TP200

Polishing time: 12mins

Material: Stainless steel

Manufacturing : Stamped parts

Polishing machine: SP5000

Polishing time: 8mins

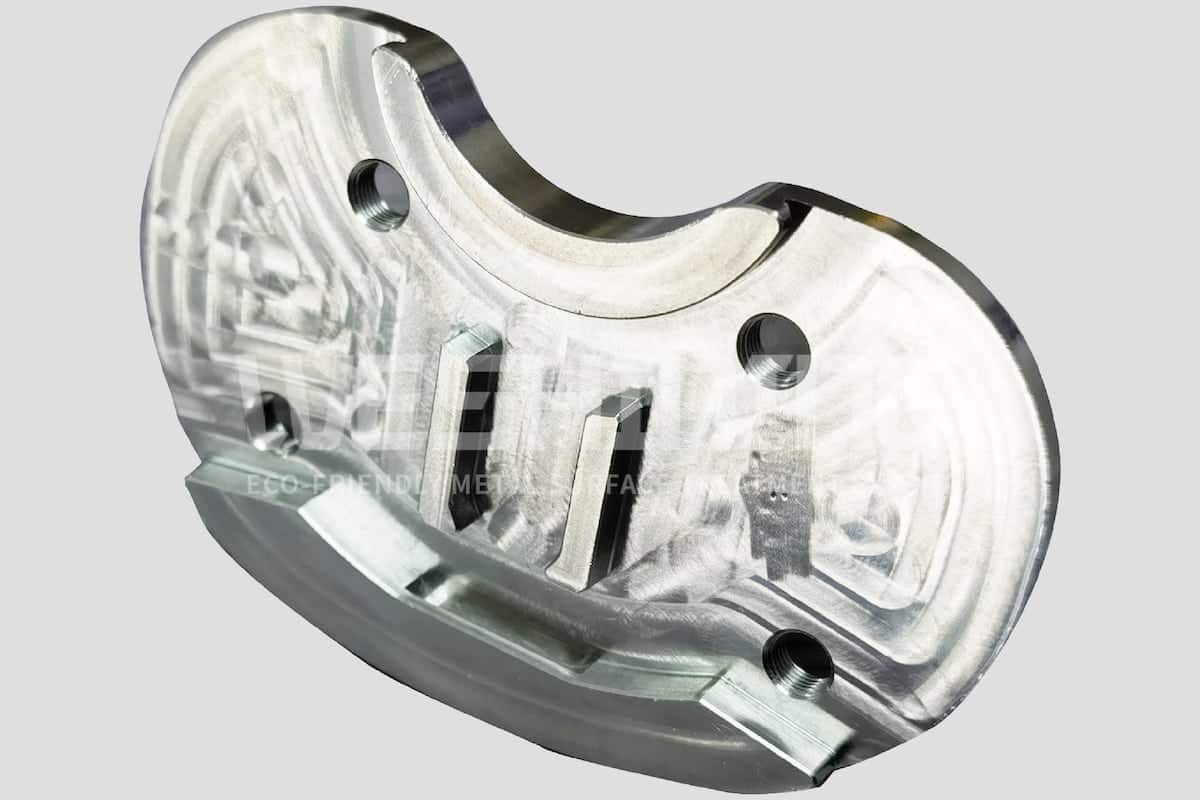

Material: Stainless steel

Manufacturing : CNC machining

Polishing machine: CP900

Polishing time: 12mins

Material: Titanium alloy

Production: 3D printing

PolishingModel: TPSeries

Polishing time: 12mins

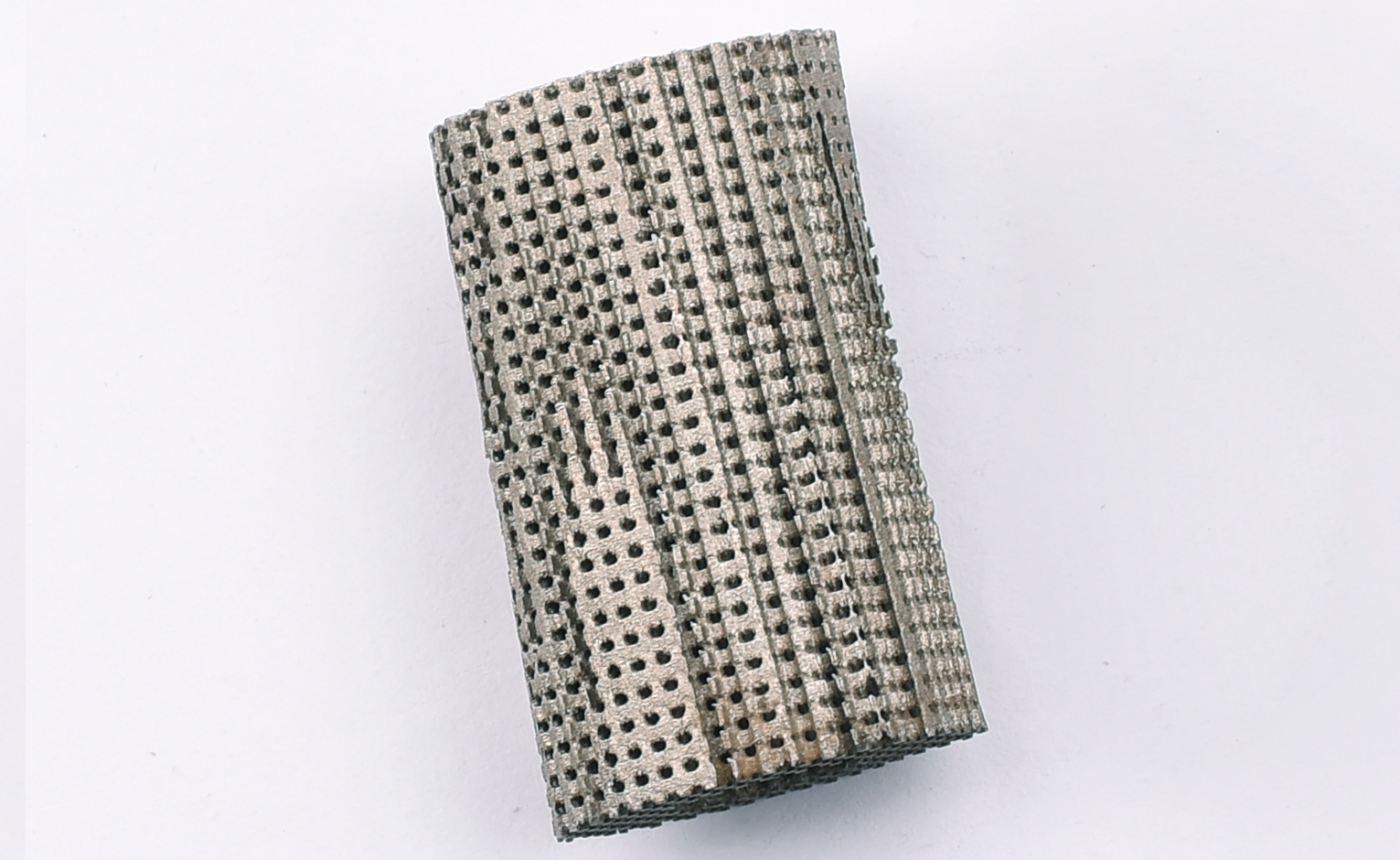

Material: Titanium alloy

Manufacturing : 3D Metal Printing Polishing machine: TP900

Polishing time: 12mins

Material: Titanium alloy

Manufacturing : Additive Manufacturing Polishing machine: TP100

Polishing time: 12mins

Metal polishing has never been easier.

Weshining team is here at your disposal.

Unlike manual polishing,Weshining polishing system takes only 3 steps, even new staff can do parts mirror bright.

It save not only your time and also save labor cost.Weshining’s automated system replaces most manual works, allowing multiple polishing steps to be completed with minimal labor. The system is characterized by high efficiency and speed.

Traditional method is harmful to staff.Weshining polishing, using neutral and environmentally friendly media,instead of toxic or corrosive chemical electrolytes,no harm to the environment or body.

Weshining polishing uses plasma generated by a high-frequency electricity to achieve a high-precision surface finishing.

The system is able to reach the blind places where machinery can’t reach. Weshining polishing system handle the complext shapes parts easily without damaging the edge of the parts.

The 25th China International High-Tech Achievements Fair (referred to as the High-Tech Fair) opened at...

Recently, the second National Postdoctoral Innovation and Entrepreneurship Competition was held in Yantai City, Shandong...

Weshining polishing system is designed for the post-processingof metal parts after casting, milling and additive manufacturingAs a professional polishing machine manufacturer in China,Weshining has been in innovative polishing technology over 9years, handling projects of different scales and complexities fromsmall to large production.