Industrial Products Metal Polishing Solution

Weshining : Eco-Friendly Metal Surface Treatment Expert

Weshining is a pioneer in advocating environmental protection in metal polishing, and also a leading supplier of metal surface finishing for 3D printing and CNC cutting automation industries. With the innovative Weshining metal polishing machine, we are at the forefront of technology and quality in high-end metal polishing solutions.

Industry Insight: Lack Of Automated Metal Post-Processing In Industry 4.0

Industry 4.0 is a new generation of industrial revolution centered on intelligent manufacturing, which requires high automation, digitization, and intelligence in all aspects of the industrial production process. However, in Industry 4.0, an important aspect is often overlooked, which is metal post-treatment.

At present, most metal post-treatment processes still rely on manual operations. It lacks automated and intelligent equipment and systems which will cause high costs, low efficiency, poor quality and environmental pollution in metal post-treatment.

Ideal for precision and efficiency in 3d printing, CNC machining and other metal part processing

Our advanced treatments enhance the durability, performance, and aesthetic appeal of metal components, ensuring they meet the stringent quality standards demanded by modern manufacturing processes. By integrating seamlessly with existing production lines, our solutions offer a streamlined approach to achieving superior finishes, making them an indispensable asset for businesses looking to optimize their manufacturing capabilities and deliver products of unmatched quality.

Weshining Plasma Polishing System

Weshining Polymer Polishing System

Surface Treatment Services

Polishing material like stainless steel, copper, zinc alloy and other materials for tableware, stamping parts and die-casting parts.

Customized Production Line

Provide feasible technical and production line customized solutions for various hardware components.

Technical Research & Equipment Development

We have supports from provincial scientific research team and professional factories, which can cooperate with customers to solve production needs.

Laboratory Testing

We have advanced experimental equipment and experienced technician to provide testing services to customers.

Competence In Titanium & Stainless Steel

We have achieved significant technological breakthroughs and successful cases in processing stainless steel and titanium metal parts. Excellent surface quality, as well as high efficiency will be our competitiveness.

Titanium

Stainless Steel

Weshining Production Advantages

9 years of experience in technology research and application, we have unparalleled production advantages.

High Quality Surface Smoothness And Brightness

We use the most advanced metal precision machining system to ensure the highest quality of metal surface treatment.

- Achieve mirror surface, even irregular surfaces

- Remove surface of nano-trace substances

- Handle complex shaped workpieces and reach blind corners that cannot be reached by machinery

- Will not cause any mechanical deformation or damage to the parts

High Efficiency Polishing For Large Production

Our automated system replaces most manual operations and complete multiple polishing steps with minimal labor. This is a decisive advantage in the need for mass production.

- Compared to traditional methods, it reduces the processes by half

- Fast polishing, can be completed in a few minutes

- High consistency, capable of multiple parts and mass processing

- Greatly reduce fixed costs such as labor, consumables

More environmentally friendly and energy-saving solutions

Weshining system replaces traditional electrolytes with neutral media, which is an energy-saving and environmentally friendly polishing process.

- Less energy is consumed per unit of material removed

- No any acidic or corrosive chemicals

- Discharges can be easily processed through standardization

- Supporting treatment equipment for chosse to meet the strict environmental regulations

Cases

We look forward to working together with you to improve the quality and performance of the products

General Purpose Workpieces

Material: Titanium alloy

Manufacturing : Additive Manufacturing

Polishing machine: Plasma Machine Series

Polishing time: 8mins

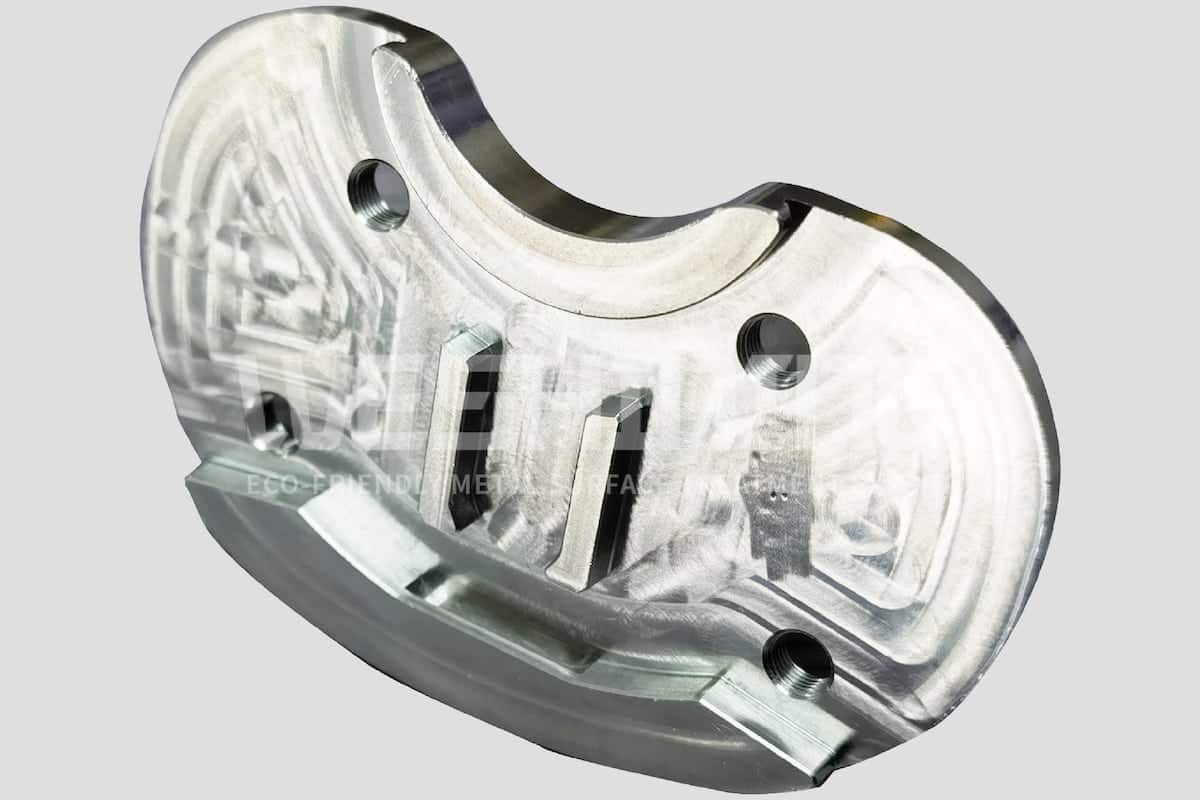

Industrial Part

Material: Stainless steel

Manufacturing : CNC machining

Polishing machine: CP900

Polishing time: 12mins

Industrial Part

Material: Stainless steel

Manufacturing : Metal 3d printing

Polishing machine: CP900

Polishing time: 15mins

Send Samples For Testing

Are you looking for an environmentally friendly and efficient solution for automated metal surface treatment? We sincerely invite you to personally observe and experience our products.

Choose The Suitable Models For Your Production Needs

Weshining industrial metal polishing system is designed for helping you to standardize your mass production lines. Our metal polishing machine is specifically designed for precision metal parts to do the precision finishing. We provide efficient and powerful solutions for high-quality and large quantity parts post-processing.

TP 950

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

TP 200

For high-quality metal parts, with extremely high flexibility, capable of handling titanium and stainless steel.

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

SP 5000

Large capacity to increase productivity by 4 times, suitable for large-scale industrial product manufacturing.

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

Related News

The 25th China International High-Tech Achievements Fair (referred to as the High-Tech Fair) opened at...

Recently, the second National Postdoctoral Innovation and Entrepreneurship Competition was held in Yantai City, Shandong...