Solutions For The Healthcare Industry

Weshining : Eco-Friendly Metal Surface Treatment Expert

Weshining is a pioneer in environmental protection in the field of metal polishing and also a leading manufacturer of metal surface finishing machines for 3D printing and CNC industries. Our innovative metal polishing solutions are at the leading edge of high-end quality market.

Industry Insight: Medical Parts Extremely High Requirements For Metal Surface Treatment Due To Their Unique Application And Materials

Medical parts are usually made of tough, slow wear and corrosion-resistant metals, such as titanium and chromium alloys. There are certain difficulties to polish for these materials, such as titanium, which is difficult to process due to its high thermal expansion rate.

In addition,the medical parts are used or directly implanted into the human body, there are extremely high requirements for the surface treatment of the workpiece, such as surface smoothness, biocompatibility, corrosion resistance and aesthetics.

Materials Used for Medical Casting and Precision Machining Parts

Products and instruments used in medical and dental fields are under strict regulation to ensure they can perform the task as intended while keeping patients safe in the process. And that’s where our eco-friendly metal polishing can help. Metal polishing procedures don’t just help improve the overall quality, but they can also help enhance product longevity, enhance durability, and make it more sterile to boot.

Weshining Plasma Polishing System

Weshining Polymer Polishing System

Surface Treatment Services

We undertake surface processing services for medical device parts, and can polish implants, bone nails, and bone splints made of titanium alloy, cobalt chrome alloy, and other materials.

Customized Production Line

We can develop automated polishing solutions to fit your needs for the customized processes required for critical medical components.

Technical Research & Equipment Development

We have supports from provincial scientific research team and professional factories, which can cooperate with customers to solve production needs.

Laboratory Testing

We have advanced experimental equipment and experienced technician to provide testing services to customers

Competence In Titanium

Weshining is a leading supplier for post-treatment of titanium and titanium alloys. Titanium metal is difficult to polish due to its high thermal expansion rate. With the help of Weshining system, you will achieve excellent surface results.

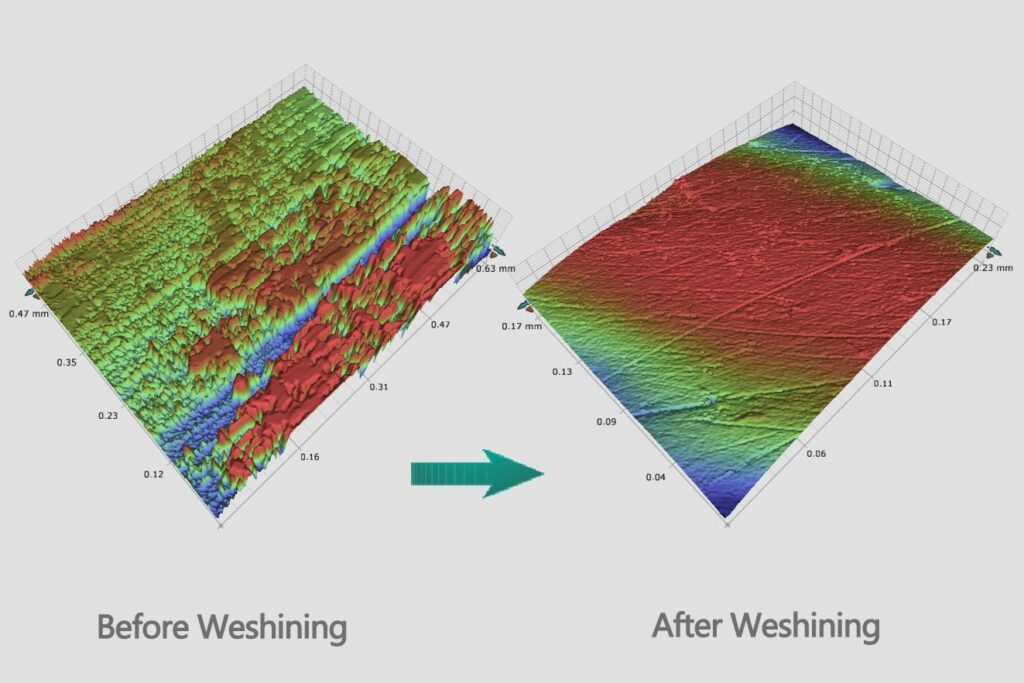

1. Uniform And Consistent Smoothness

Smooth surface improves the performance of medical parts (such as antibacterial and durability) and patient comfort.

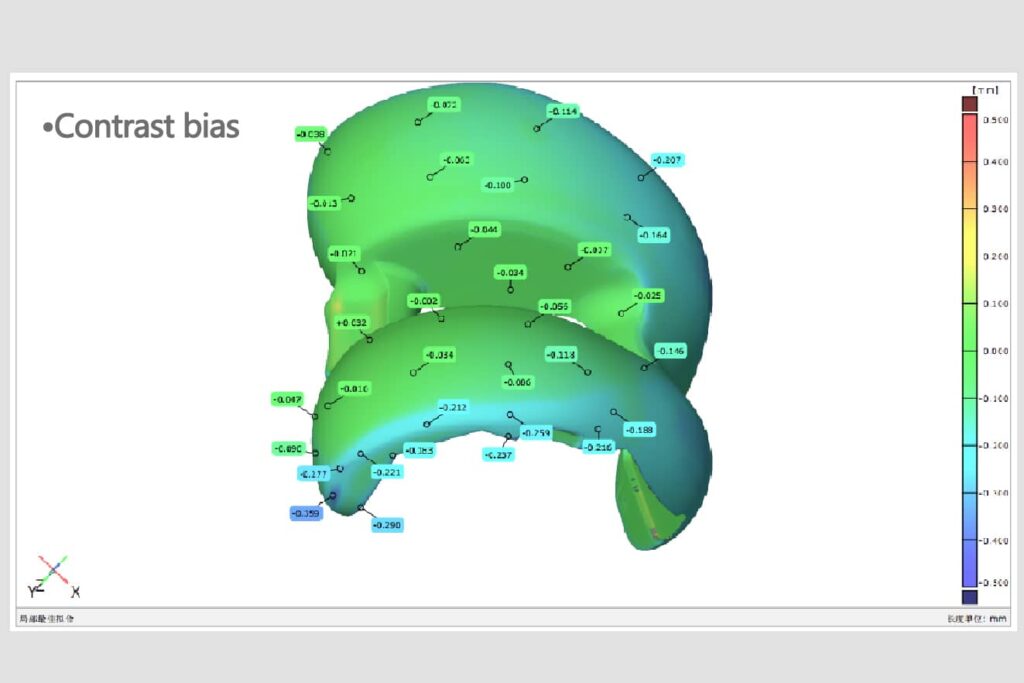

2. Overall Polishing With Controllable Wear And Tear

This avoids the problem of uneven polishing and keeps the shape of the workpiece unchanged.

3. Meet Medical Device Safety Standards

The environmentally friendly processes that do not contain hazardous chemicals to prevent harmful substances from remaining on the surface.

Weshining Production Advantages

Rich experience in research and application, we have unparalleled production advantages.

High Quality Surface Smoothness And Brightness

We use the most advanced metal precision machining system to ensure the highest quality of metal surface treatment.

- Achieve mirror surface, even irregular surfaces

- Remove surface of nano-trace substances

- Handle complex shaped workpieces and reach blind corners that cannot be reached by machinery

- Will not cause any mechanical deformation or damage to the parts

High Efficiency Polishing For Large Production

Our automated system replaces most manual operations and complete multiple polishing steps with minimal labor. This is a decisive advantage in the need for mass production.

- Compared to traditional methods, it reduces the processes by half

- Fast polishing, can be completed in a few minutes

- High consistency, capable of multiple parts and mass processing

- Greatly reduce fixed costs such as labor, consumables

Certified Environmental Protection And Safety

Weshining system replaces traditional electrolytes with neutral media, which is an environmentally friendly and safe polishing process, confirmed by certifications including EU CE, ISO 9001, and MSDS.

- ess energy is consumed per unit of material removed

- No any acidic or corrosive chemicals

- Discharges can be easily processed through standardization

- Supporting treatment equipment for chosse to meet the strict environmental regulations

Cases

We look forward to working together with you to improve the quality and performance of the products.

Bone implant

Material: Titanium alloy

Manufacturing : 3D Metal Printing Polishing machine: TP900

Polishing time: 12mins

Hip Joint

Material: Titanium alloy

Manufacturing : 3D Metal Printing Polishing machine: TP100

Polishing time: 15mins

Skeletal Implants

Material: Titanium alloy

Manufacturing : Additive Manufacturing Polishing machine: TP100

Polishing time: 12mins

Send Samples For Testing

Are you looking for an environmentally friendly and efficient solution for automated metal surface treatment? We sincerely invite you to personally observe and experience our products.

Choose the suitable models for your production needs

CP900

High efficiency and affordable, suitable for small metal parts in dental and medical business.

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

TP900

Affordable desktop model, suitable for the dental labs and medical industries.

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

TP100

Combo model for handling Titanium and Cobalt Chromium parts need mirror surface.

Suitable for large-scale industrial parts manufacturing. It helps increase productivity by four times

Related News

The 25th China International High-Tech Achievements Fair (referred to as the High-Tech Fair) opened at...

Recently, the second National Postdoctoral Innovation and Entrepreneurship Competition was held in Yantai City, Shandong...