Weshining plasma polishing technology is an advanced process. With the plasma, nanoscale materials from metal surfaces are removed, improving surface quality and shiny.

The material removal speed is 10-30 times faster than traditional electrolytic polishing. In addition, the plasma polishing process is completely free of harmful substances to the environment, making it an ideal choice for reliable, efficient and environmentally friendly metal finishing.

Dentistry, medical, energy development

1-3pcs/circle

Dentistry, medical, energy development

3-6pcs/circle

Industry, Luxury & Fashion, Consumer electronics, Moulds, Aerospace

250-300pcs/circle

Dentistry, Medical, Additive manufacturing

1-3pcs/circle

Dentistry, Medical, Automotive, Industry

3-6pcs/circle

Dentistry, medical

Ti 3pcs/circle,Cocr 3pcs/circle

Dentistry, medical

Ti 3pcs/circle,Cocr 6pcs/circle

Dentistry, medical

Customized

Material: Titanium alloy

Production: 3D printing

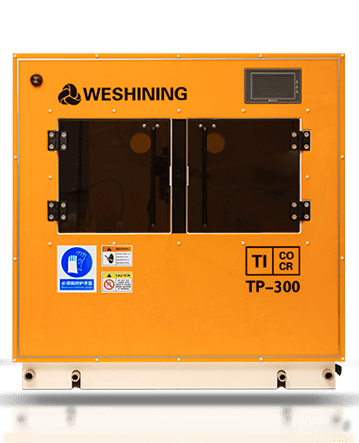

PolishingModel: TPSeries

Polishing time: 12mins

Material: Titanium alloy

Manufacturing : 3D Metal Printing Polishing machine: TP900

Polishing time: 12mins

Material: Stainless steel

Manufacturing : Stamped parts

Polishing machine: SP5000

Polishing time: 8mins

Know more about Weshining Plasma Polishing machine.

Our technical team is one of the teams that started research on eco metal surface treatment early from 2015. We have rich experience metal polishing processes.

We work with national & provincial science platform, a Ph.D. scientific research workstations which enables us to continuously improve our technology and processes, ensuring that we stay at the forefront of the industry.

With plasma generated by high-frequency electricity, Weshining achieve high-speed, efficient and high-precision surface treatment, while traditional electrolytic polishing is slower processing speed, poor surface accuracy and consistency.

Weshining plasma polishing uses neutral and environmentally friendly media instead of toxic or corrosive chemical electrolytes, which will not cause harm to the environment and human body. However, traditional electrolytic polishing uses strong acid and corrosive solutions, which will produce harmful waste gas and wastewater.

Weshining plasma remove burrs and clean the metal surface, improving their smoothness, corrosion resistance and gloss. It meets the highest requirements in fields such as medical industry.

Weshining can handle complex shapes and parts with various materials, such as titanium, stainless steels, copper, CoCr, nitinol

Simplified the mental finishing process, which is half of the traditional process.

Weshining systems utilize advanced technology and equipment to improve the quality and performance of metal parts, ensuring that they meet the high standards and specifications of the medical industry.

Some applications of our systems in the dental industry:

-Pure titanium/titanium alloys

-Stainless steel (316/304)

-Nickel alloys

Weshining systems utilize advanced technology and equipment to improve the quality and performance of metal parts, ensuring that they meet the high standards and specifications of the medical industry.

Some applications of our systems in the dental industry:

-Pure titanium/titanium alloys

-Stainless steel (316/304)

-Nickel alloys

A pre-recorded video of general introduction, operation as well as maintenance.Online aftersales consultation with our professional technician team.

Upgrading the metal polishing equipment, including upgrading the various sensors, electrical systems, operating systems and other systems and functions.

Provide customers with all accessories and consumables related to equipment maintenance,including: surface treatment materials, clamps holding the frames etc.

Our team will help you solve your most difficult production challenges through customized solutions on the production line. We will design and manufacture a dedicated production line that suits your product and processing ased on your needs.